Callaham Cold Rolled Steel CNC Machined Gibson Stopbar Tailpiece Callaham

$ 110,00 $ 44,00

From Callaham:

Machined from the same alloy as our ABR-1 bridge, use of our steel tailpiece will improve note definition and widen frequency response in Gibson style guitars. The tone change is comparable to changing a dead set of strings to a new set of strings. Coupled with our steel ABR-1 bridge, the instrument starts to take on piano like qualities. Notes are crisp yet smooth, and with the proper technique one can create a wide variety of tones simply by altering their touch. With a more responsive instrument, you may find yourself using less extreme settings on your amplifier. You should be able to flatten out the response so that switching from bridge to neck is more balanced.

I am always amused by the claims that an aluminum tailpiece adds sustain. Aluminum will NEVER come close to the sustain produced by our steel tailpiece.

As with all of our products, we do not believe in repeating the mistakes of the past. The original 50’s tailpieces were made from aluminum because it was easy and cheap. Producing a tailpiece from steel and machining it is three times as difficult, but it is the best material if you are concerned with your sound. The myth that weight or mass is an imporant property of guitar hardware has no basis in science and is completely false. Thus, the same principles that apply to our strat tremelo block also apply to this tailpiece.

Our tailpiece is compatible with stock Gibson studs and most aftermarket studs. With the steel tailpiece the effects of the studs is minimal. We do suggest the studs are tightened down firmly.

We were concerned with maintaining the vintage look, and with the help of customers with original 50’s tailpieces we have succeeded. After machining, the tailpieces are sanded and polished by hand to recreate the same look and feel of an original. We do not purposely try to recreate the flaws that so many of the originals exhibit. Having said that, we do not try to make them look exactly identical from part to part. They each have their own unique identity due to the handwork performed during the final stages of production. They are only available in nickel plating, which is done with care yielding a graceful finish, unlike the plating on many other aftermarket tailpieces

Fast Shipping with Professional Packaging

We offer a wide range of shipping options due to our long-standing partnerships with UPS, FedEx and DHL. Our warehouse staff are trained to pack your goods exactly according to the specifications we offer. Before shipping the goods are thoroughly examined and secured. Every day, we send thousands of packages to clients from all over the world. Our determination to be the biggest online retailer in the world is shown by this. The warehouses are located in Europe as much as they are in USA.

Note: Orders with more than one product will be assigned a distinct processing time, dependent on the particular item.

Before shipping, we will examine the items ordered thoroughly before sending the items. The majority of orders are shipped within 48 hrs. The delivery estimate is between 3-7 days.

Returns

The stock is constantly changing and cannot be fully controlled by us because of the involvement of several parties including the factory and our warehouse. Stock levels can fluctuate at any given time. Please be aware that it is possible that your order could become unavailable even after you've placed your order.

Our policy is valid for a period of 30 days. If 30 days have passed by since your purchase however, we're unable to give an exchange or refund.

In order to be eligible for a refund your product must be unopened and in the same state as you received it. It should also be in the original package.

Related products

Drums and Percussion / Cymbals / Hi-Hats

Parts / Amp Parts

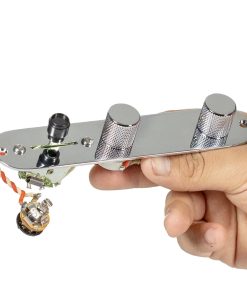

920D Custom JB-CON-CH-BK Upgraded Replacement ’62 Jazz Bass Concentric Control Plate 920D Custom

Keyboards and Synths / Synths / Eurorack

Amps / Guitar Cabinets

3rd Power Amplification Dual Citizen 2-Channel 40-Watt Head w/ 2×12 Cab 3rd Power Amplification

Amps / Guitar Cabinets

3rd Power Amplification Kitchen Sink Guitar Head 3rd Power Amplification

Accessories / Books and DVDs

Amps / Guitar Cabinets

3rd Power Amplification 2×12″ Guitar Speaker Cab 3rd Power Amplification

Effects and Pedals / Overdrive and Boost

Accessories / Books and DVDs

Amps / Guitar Cabinets

1695T Black Magick 25-Watt 1×12″ Guitar Combo Chicago Music Exchange

Accessories / Merchandise

Effects and Pedals / Overdrive and Boost

1981 Inventions DRV Overdrive White Hyperfade 1981 Inventions

Effects and Pedals / Overdrive and Boost

Effects and Pedals / Overdrive and Boost

Effects and Pedals / Preamps

Effects and Pedals / Overdrive and Boost

29 Pedals Special Run Crunch Berry EUNA Elite Unity Amplifier Input Driver 29 Pedals

Effects and Pedals / Overdrive and Boost

Drums and Percussion / Acoustic Drums / Snare

A&F Drum Co. 1.75×12 Pancake Raw Brass Snare Drum A&F Drum Co.

Accessories / Books and DVDs

Effects and Pedals / Wahs and Filters

Effects and Pedals / Overdrive and Boost

Drums and Percussion / Acoustic Drums / Full Acoustic Kits

A&F Drum Co. 12/14/18 3pc. Walnut Club Drum Kit A&F Drum Co.

Drums and Percussion / Parts and Accessories / Drum Parts

Effects and Pedals / Overdrive and Boost

1981 Inventions Special Edition Stranger DRV Overdrive Pedal 1981 Inventions

Parts / Amp Parts

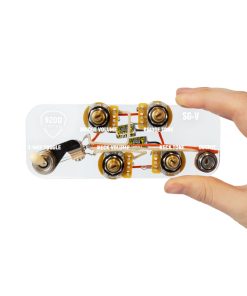

920D Custom ES335-JP Wiring Harness for Gibson/Epiphone ES-335 w/Four Push/Pulls 920D Custom

Keyboards and Synths / Synths / Eurorack

Keyboards and Synths / Synths / Eurorack

Parts / Amp Parts

Amps / Guitar Heads

Drums and Percussion

20″ Craig Lauritsen Custom Rustico Crash Ride Cymbal USED Chicago Music Exchange